Our X Series

Your FAQs, Our Expert Answers.

Frequently Asked Questions about the X Series

What is the X Series?

X Series is a family of products that have been developed over years of study and trial. The product line is proprietary in nature and were developed to liberate hydrocarbons from a variety of materials and media.

All X Series products share basic and inherent characteristics to act with hydrocarbons on a molecular level and cause them to lose their attraction to water, metals, minerals, and other particulate matter. X Series are atmospheric and initiate ionic exchange to facilitate separation of materials.

Why does it work on hydrocarbons?

When the X Series products contact oil/hydrocarbons it acts as a surfactant, by reducing surface tension, and breaks the molecular bond of oil to other materials. Once the bond is broken between oil and other materials, X Series products enhance the natural tendency of the oil to be hydrophobic and colloidal1, thus promoting efficient separation. However, unlike common surfactants, X Series products are derived from inorganic materials and will not form an emulsion.

How does it work in downhole environments?

Many variables exist in oil formations, including mineral composition, temperature, pressure, oil type and quality, water type, and the presence of many compounds that affect the ability to produce oil/gas. X Series products are designed to work within a wide array of variables encountered in hydrocarbon formations. Its basic functions are to release oil, enhance flow characteristics (increased permeability), reduce corrosion, disperse paraffin and asphaltenes, and provide protection to metal production components. X Series products performs these in most environments and formation types. * Disjoining Pressure2, Brownian Motion3

1 Colloidal Dispersion – a system, in which particles, droplets or bubbles of a dispersed phase, whose size at least in one dimension is in the range from 1-1,000 nm, are distributed in the other, usually continuous phase {dispersion medium} differing from the dispersed phase in composition or state of aggregation)

2 Disjoining Pressure – in surface chemistry, arises from an attractive interaction between two surfaces. For two flat and parallel surfaces, the value of the disjoining pressure (i.e., the force per unit area) can be calculated as the derivative of the Gibbs energy of interaction per unit area in respect to distance (in the direction normal to that of the interacting surfaces). There is also a related concept of disjoining force, which can be viewed as disjoining pressure times the surface area of the interacting surfaces.

3 Brownian Motion – the erratic random movement of microscopic particles in a fluid, as a result of continuous bombardment from molecules of the surrounding medium.

How does the X Series work with water?

X Series is a contact compound and uses water as a carrier. It readily disperses in water and is soluble. The X Series will reside in the water and does not mix with or change the characteristics of the oil.

Are X Series products surfactants?

No. X Series products have surfactant like qualities in that they readily reduce surface tension that allows oil and gas to release from other materials. X Series products are derived from inorganic materials; surfactants are typically made from organic materials which possess entirely different chemical properties.

Does the X Series inhibit corrosion?

Yes, when designed as a corrosion inhibition product X Series Corrosion Inhibitor inhibits corrosion in several ways, it is an extreme oxygen scavenger and will draw and bind free oxygen when it can. Oxygen is one of the most prolific causes of corrosion and chemically binds with many compounds to form corrosive materials in the form of sulfides, oxides, and sulfates. These corrosive compounds and many bacteria thrive in an aerobic environment. X Series Corrosion Inhibitor products effectively binds the oxygen and destroys the corrosive issues. Additionally, X Series Corrosion Inhibitor products are highly negative in conductivity which promotes its ability to initiate ionic exchange. This combined with a silicon component in the formula make the X Series Corrosion Inhibitor products attracted to metal. X Series Corrosion Inhibitor products readily bond to metal production components leaving a microscopic layer of protection.

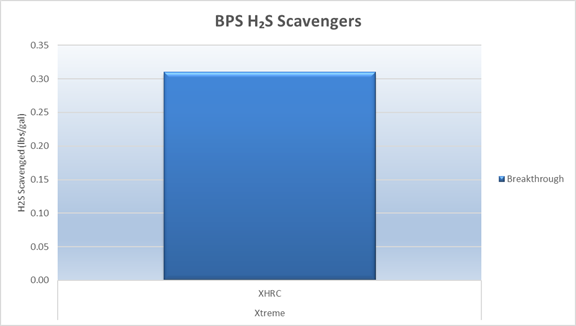

Does the X Series affect H2S?

Yes, when designed as a H2S treatment product will reduce the corrosive effects of H2S by breaking the bond of hydrogen and sulfur.

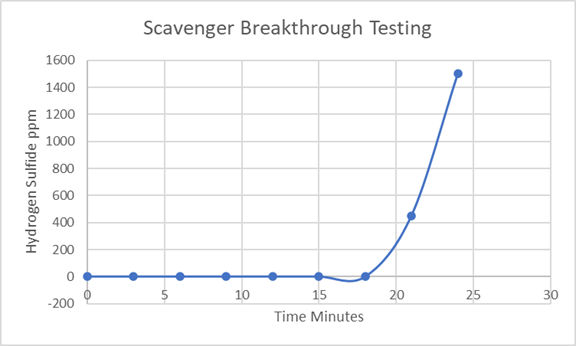

Hydrogen Sulfide Scavenger Testing Test Method The procedure utilized in the hydrogen sulfide scavenger testing is as follows:

- Product is measured and placed in the testing container.

- Gas supply is attached to test apparatus.

- System is checked for leaks prior to beginning test.

- Gas valve is opened, and flow rate is set.

- H2S is bubbled through the product being tested.

- Treatment is continued until H2S is no longer consumed by the product and H2S is carried over to the detector.

- Once H2S detector reaches 1500ppm, H2S supply is re-directed from the meter.

- Time for breakthrough is recorded.

- H2S continues being bubbled for 30 minutes after breakthrough.

- H2S uptake of the product is calculated out to reported values.

Results Test is designed to bubble a hydrogen sulfide containing gas through the scavenger to simulate gas phase treatment.

The test gas is composed of 10% H2S in nitrogen and fed to the system at a rate of 241.69 mL/min. The gas is highly dispersed using a fritted glass cylinder to ensure maximum contact. Reaction is continued until rapid increase is seen from H2S carried over from the scavenger container. H2S consumed is calculated based on flow rate of gas and time of flow. Simulation of this nature does not produce a completely spent product in most chemistries but reaches a point where efficiency of H2S reaction greatly declines. Apparatus used is shown below with portion used for H2S supply on the left and sparging tower and trap on the right. Tubing connects the gas supply to sparging and tubing leaving the trap is lead to an H2S analyzer to determine H2S breakthrough during testing.

What effect does the X Series have on paraffin & asphaltenes?

When coupled with Xtreme Performance Chemicals, LLC paraffin line of products it works as a solvent to breakdown paraffin build up. Once the paraffin is broken down it remains suspended in the produced oil to be carried out of the well. What makes this product line so unique is the X Series’ molecular charge and the ionic exchange. The X Series initially coats and leaves a microscopic film on the production tubing. This penetrates the build-up along the surface of the pipe. Once this has taken place the microscopic barrier that now exists releases build-up and now reduces surface tension which keeps the paraffin from adhering to the pipe walls. The secondary reaction that occurs is the X Series now begins to interact with the hydrocarbons, forcing them to release BS&W contained within the oil. At that point the X Series suspends the paraffin and carries it through the production system without the choke points associated with many of the other paraffin products in use, typical applications are in the 250 ppm – 750 ppm range.

What is The X Series?

X Series is a well clean up, frac flowback aid & EOR product, It embodies the basic characteristics of the xHRC XS Series products to release oil. However, X Series is designed to target clean-up of the production string near the wellbore matrix of the formation. Many wells are plagued with production and mechanical issues resulting from fouling and corrosion. X Series is designed to open pore channels and increase permeability that have been compromised from years of production. Further, production tubing and equipment can become fouled from many corrosive materials and bacteria that compromise performance and increase cost. X Series effectively cleans corrosion and provides a protective layer to equipment that reduces fouling.

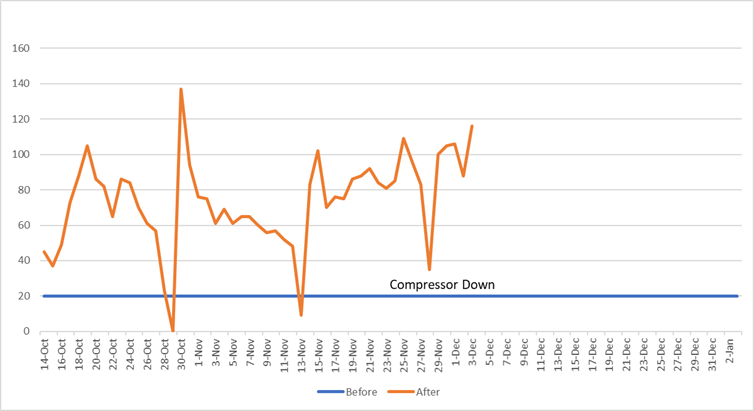

Cotton Valley well. Was making an estimated 20mcfd and no water prior to treating. Now making almost 120 and 25bbls of water per day. They installed an automatic soap dispenser in November and you can see the nice upwards trend afterwards.

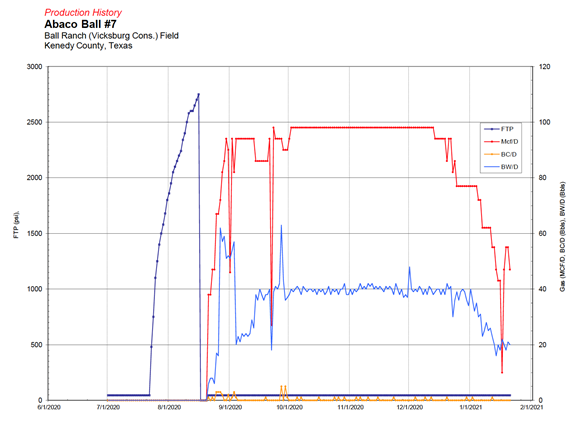

Vicksburg Formation

Click the links below for some more insight into the technology.

What does the X Series of products do to perforations?

Perforations that are fouled and choking off fluid entry from corrosion, scale, bacteria or other hydrocarbon buildups will benefit from a treatment by cleaning and opening the perforations. Once cleaned, X Series will deposit a molecular coating making those deposits less likely to attach to the perforations.

Will the X Series of products harm my equipment?

No, quite the opposite in fact. X Series products will improve metal production components by cleaning and leaving a layer of protection to reduce further problems. X Series products will act as a DRA reducing interfacial tension and surface tension. In pipeline applications, including gathering lines X Series, currently in the Permian Basin has reduced H2S by as much as 4%, BS&W issues are non-existent, Valve maintenance due to scale and fouling have been negated, Paraffin fouling in the gathering system has been negated and iron sulfide problems have been significantly reduced. In previous pipeline applications pig runs have been negated by as much as 80%.

Email: [email protected]

CONTACT

Call: +1 (361) 649-0089

LOCATION

3338 Old Yoakum Rd. Cuero, TX 77954